How can CNC machined parts inside automotive automated equipment reduce friction and wear during operation?

Release Time : 2025-12-12

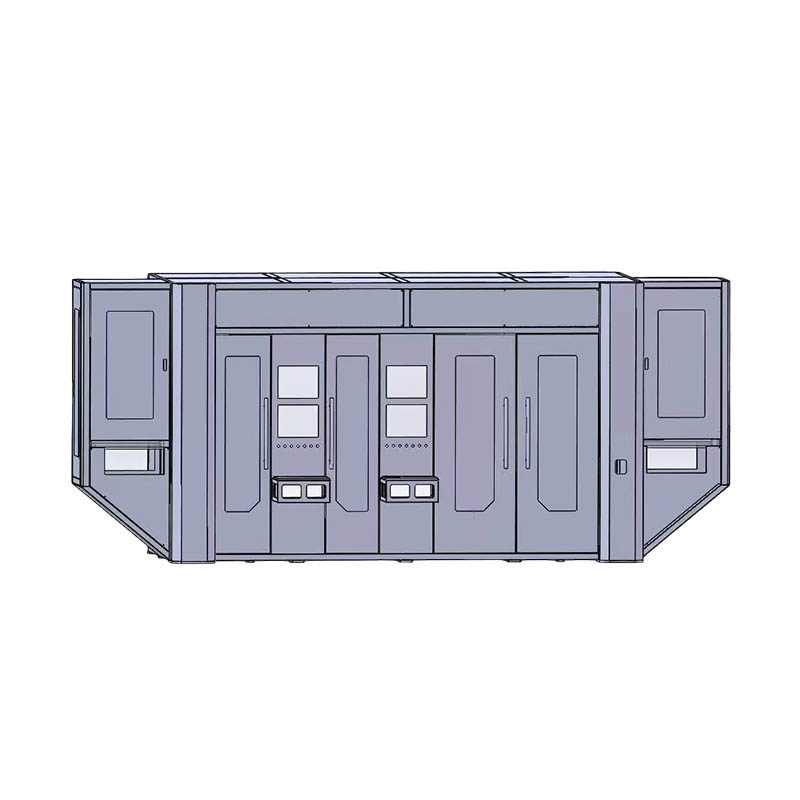

In modern automotive manufacturing systems, automated equipment is the core support for ensuring high efficiency, high precision, and high consistency. The CNC machined parts inside these machines operate under high-speed, high-frequency, heavy-load, and even harsh environments for extended periods, making them highly susceptible to friction and wear, leading to decreased precision, shortened lifespan, or even sudden shutdowns. Therefore, effectively reducing friction and wear during operation has become a key issue in improving the reliability and economy of automotive automated equipment.

1. Material Selection: Enhancing Wear Resistance from the Source

The first line of defense against friction and wear lies in the materials themselves. High-hardness alloy steel, tool steel, or stainless steel are commonly used as the base material for CNC machined parts inside automotive automated equipment to ensure basic strength and dimensional stability. For high-frequency sliding areas, engineering plastics or self-lubricating metal-based composite materials are widely used. For example, copper alloy bushings containing molybdenum disulfide or graphite can form a solid lubricating film without external lubrication, significantly reducing the coefficient of friction. In addition, some key components utilize ceramic coatings or tungsten carbide spraying to further enhance surface hardness and corrosion resistance, constructing a physical barrier of "low friction and high wear resistance" at the material level.

2. Precision Machining and Surface Treatment: Creating Ultra-Low Roughness and Reinforced Surfaces

Even with superior materials, surface roughness or microscopic defects will still accelerate wear. Therefore, high-precision grinding, ultra-precision machining, and mirror polishing are widely used in core transmission components such as guideways and ball screws to minimize microscopic seizing and ploughing effects at the contact surfaces. Simultaneously, surface strengthening technologies such as carburizing, nitriding, QPQ, or physical vapor deposition form a modified layer with high hardness and low friction on the component surface. For example, nitriding can achieve a surface hardness of over 1000 HV for steel parts, providing excellent fatigue resistance and anti-adhesive wear capabilities, effectively extending the service life of components.

3. Lubrication System Design: Constructing a Dynamic Lubrication Protective Film

Even the best materials and surfaces cannot function without the synergistic effect of lubrication. Modern automotive automated equipment is generally equipped with centralized lubrication systems, which inject high-performance grease or oil into moving parts at regular intervals and in precise quantities. For high-speed, light-load applications, low-viscosity synthetic oils are often chosen; while for heavy-load, low-speed conditions, high-adhesion greases containing extreme pressure additives are preferred. More advanced solutions include oil-air lubrication or micro-lubrication, using a very small amount of lubricating medium to form a stable oil film between friction pairs, reducing energy consumption and contamination while avoiding the oil sludge buildup problems caused by traditional excessive lubrication. Furthermore, the design of the sealing structure is also crucial, preventing external contaminants from entering while ensuring that the lubricating medium does not leak or fail.

4. Structural Optimization and Intelligent Monitoring: From Passive Protection to Active Prevention

Besides "hard" measures, the structural design of CNC machined parts also affects friction and wear behavior. For example, using rolling instead of sliding, optimizing contact stress distribution, and reducing unnecessary degrees of freedom can all reduce frictional power consumption at its source. In recent years, with the advancement of Industry 4.0, more and more equipment is integrating vibration, temperature, or acoustic emission sensors into key components. By monitoring changes in friction conditions in real time, these sensors predict wear trends and trigger maintenance reminders before malfunctions occur, thus shifting from "routine maintenance" to "predictive maintenance."

Reducing friction and wear on CNC machined parts within automotive automated equipment is a systematic engineering project integrating materials science, precision manufacturing, lubrication engineering, and intelligent sensing. Only through coordinated efforts across the four dimensions of materials, processes, lubrication, and design can equipment remain "as smooth as new" after millions of cycles, providing solid support for the efficiency, stability, and intelligence of the automotive manufacturing industry.

1. Material Selection: Enhancing Wear Resistance from the Source

The first line of defense against friction and wear lies in the materials themselves. High-hardness alloy steel, tool steel, or stainless steel are commonly used as the base material for CNC machined parts inside automotive automated equipment to ensure basic strength and dimensional stability. For high-frequency sliding areas, engineering plastics or self-lubricating metal-based composite materials are widely used. For example, copper alloy bushings containing molybdenum disulfide or graphite can form a solid lubricating film without external lubrication, significantly reducing the coefficient of friction. In addition, some key components utilize ceramic coatings or tungsten carbide spraying to further enhance surface hardness and corrosion resistance, constructing a physical barrier of "low friction and high wear resistance" at the material level.

2. Precision Machining and Surface Treatment: Creating Ultra-Low Roughness and Reinforced Surfaces

Even with superior materials, surface roughness or microscopic defects will still accelerate wear. Therefore, high-precision grinding, ultra-precision machining, and mirror polishing are widely used in core transmission components such as guideways and ball screws to minimize microscopic seizing and ploughing effects at the contact surfaces. Simultaneously, surface strengthening technologies such as carburizing, nitriding, QPQ, or physical vapor deposition form a modified layer with high hardness and low friction on the component surface. For example, nitriding can achieve a surface hardness of over 1000 HV for steel parts, providing excellent fatigue resistance and anti-adhesive wear capabilities, effectively extending the service life of components.

3. Lubrication System Design: Constructing a Dynamic Lubrication Protective Film

Even the best materials and surfaces cannot function without the synergistic effect of lubrication. Modern automotive automated equipment is generally equipped with centralized lubrication systems, which inject high-performance grease or oil into moving parts at regular intervals and in precise quantities. For high-speed, light-load applications, low-viscosity synthetic oils are often chosen; while for heavy-load, low-speed conditions, high-adhesion greases containing extreme pressure additives are preferred. More advanced solutions include oil-air lubrication or micro-lubrication, using a very small amount of lubricating medium to form a stable oil film between friction pairs, reducing energy consumption and contamination while avoiding the oil sludge buildup problems caused by traditional excessive lubrication. Furthermore, the design of the sealing structure is also crucial, preventing external contaminants from entering while ensuring that the lubricating medium does not leak or fail.

4. Structural Optimization and Intelligent Monitoring: From Passive Protection to Active Prevention

Besides "hard" measures, the structural design of CNC machined parts also affects friction and wear behavior. For example, using rolling instead of sliding, optimizing contact stress distribution, and reducing unnecessary degrees of freedom can all reduce frictional power consumption at its source. In recent years, with the advancement of Industry 4.0, more and more equipment is integrating vibration, temperature, or acoustic emission sensors into key components. By monitoring changes in friction conditions in real time, these sensors predict wear trends and trigger maintenance reminders before malfunctions occur, thus shifting from "routine maintenance" to "predictive maintenance."

Reducing friction and wear on CNC machined parts within automotive automated equipment is a systematic engineering project integrating materials science, precision manufacturing, lubrication engineering, and intelligent sensing. Only through coordinated efforts across the four dimensions of materials, processes, lubrication, and design can equipment remain "as smooth as new" after millions of cycles, providing solid support for the efficiency, stability, and intelligence of the automotive manufacturing industry.