How to ensure long-term repeatability of frame welding processing inspection tool frames under vibration conditions?

Release Time : 2025-11-14

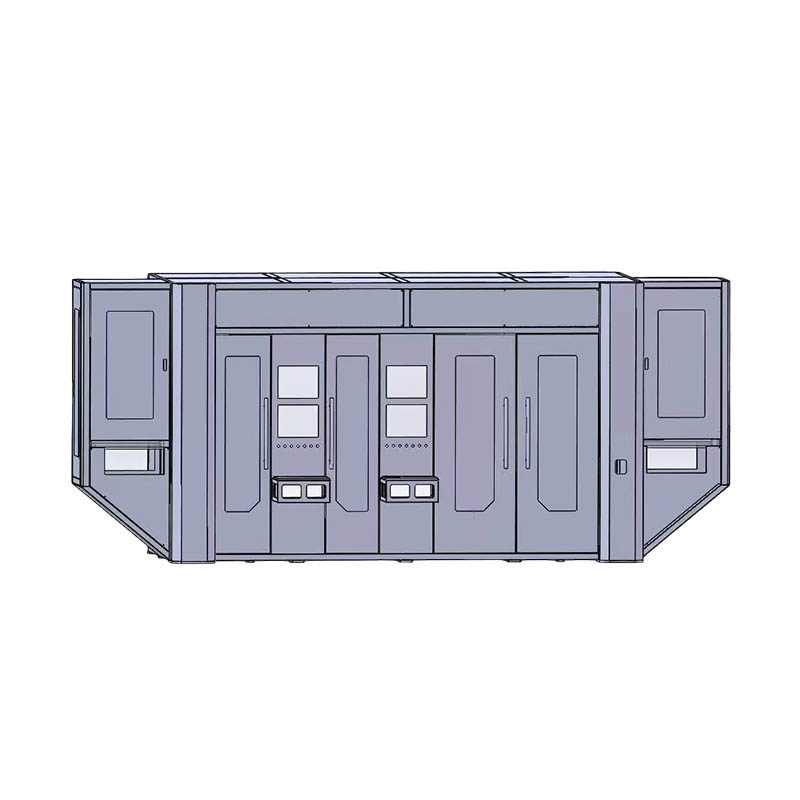

In high-end manufacturing industries such as automobile manufacturing, construction machinery, rail transportation, and new energy equipment, frame welding of large metal structural components is a critical process. To ensure post-weld dimensional accuracy and assembly consistency, inspection tool frames are widely used for rapid and reliable geometric verification of welded assemblies. However, in actual production environments, factors such as welding robot operations, pneumatic clamping device movements, workshop crane operation, and even ground micro-vibrations continuously generate mechanical vibrations, which can easily lead to loosening of the reference elements of the inspection tool frame, fatigue of connectors, or micro-deformation of the structure, thus affecting its long-term repeatability. Maintaining micron-level or even sub-millimeter-level measurement reliability under such harsh dynamic conditions has become the core challenge in the design and application of frame welding processing.

1. High-rigidity structural design: the foundation for resisting vibration disturbances

The frame welding processing body typically uses high-quality alloy steel, cast iron, or stress-relieved welded steel structures. Through reasonable cross-sectional layout and overall topology optimization, structural stiffness and natural frequencies are maximized. High rigidity not only effectively suppresses the transmission and amplification of external vibrations but also prevents elastic or plastic deformation under frequent clamping stress. Some high-end fixtures even incorporate finite element modal analysis to avoid common equipment vibration frequencies during the design phase, preventing resonance and improving vibration resistance stability from the source.

2. Precision Reference System and Anti-Loosening Connection Technology

The core of repeatability accuracy lies in the stability of the reference system. Key positioning pins, reference blocks, and clamping mechanisms in frame welding processing are all hardened, with a surface hardness exceeding HRC 58, and are fitted with high-precision tolerances. More importantly, all connecting bolts generally employ mechanical anti-loosening measures such as double-nut locking, anaerobic adhesive anti-loosening, or disc spring washers to prevent preload attenuation due to vibration. For core reference points, a composite positioning method of tapered pins and end-face contact is often used, limiting both radial displacement and axial movement, significantly improving the consistency of repeated installations.

3. Material Selection and Thermal-Mechanical Stability Control

In addition to mechanical vibration, workshop temperature fluctuations also affect dimensional stability through thermal expansion and contraction. Therefore, frame welding processing tends to use materials with low coefficients of thermal expansion, or embed temperature compensation structures within ordinary steel. Simultaneously, all welded components must undergo stress-relief annealing before processing to eliminate residual stress and prevent slow deformation due to stress release during use. This "thermal-mechanical dual stabilization" strategy ensures that even after months or years of continuous use, the reference position drift remains within ±0.05 mm.

4. Regular Calibration and Condition Monitoring Mechanism

Even the most robust structures require maintenance. Advanced manufacturing companies generally establish periodic calibration systems, using laser trackers or coordinate measuring machines to re-measure key reference points of the inspection frame. If deviations exceed limits, adjustments or repairs are immediately made. Some intelligent inspection tools integrate miniature vibration sensors and displacement monitoring modules, which can record abnormal impact events in real time and provide early warnings of potential accuracy risks within the system, achieving a shift from "passive maintenance" to "predictive maintenance."

5. Installation Foundation and Vibration Isolation Measures

The installation platform of the inspection tool frame is equally crucial. Ideally, it should be fixed to an independent concrete foundation or heavy-duty vibration isolation platform to avoid sharing vibration sources with production line equipment. Anchor bolts are chemically anchored or welded with pre-embedded steel plates to ensure a rigid overall connection. In high-precision scenarios, active or passive vibration isolation pads are even used to further attenuate low-frequency vibrations transmitted from the ground.

The frame welding processing inspection tool achieves long-term, reliable, and repeatable positioning accuracy in continuously vibrating industrial environments through the synergistic effect of five dimensions: high-rigidity structural design, precision anti-loosening reference system, material thermal stability control, intelligent monitoring, and standardized installation. This not only ensures product quality consistency but also lays a solid foundation for online quality closed-loop control in intelligent manufacturing, truly becoming an indispensable "precision guardian" in modern welding workshops.

1. High-rigidity structural design: the foundation for resisting vibration disturbances

The frame welding processing body typically uses high-quality alloy steel, cast iron, or stress-relieved welded steel structures. Through reasonable cross-sectional layout and overall topology optimization, structural stiffness and natural frequencies are maximized. High rigidity not only effectively suppresses the transmission and amplification of external vibrations but also prevents elastic or plastic deformation under frequent clamping stress. Some high-end fixtures even incorporate finite element modal analysis to avoid common equipment vibration frequencies during the design phase, preventing resonance and improving vibration resistance stability from the source.

2. Precision Reference System and Anti-Loosening Connection Technology

The core of repeatability accuracy lies in the stability of the reference system. Key positioning pins, reference blocks, and clamping mechanisms in frame welding processing are all hardened, with a surface hardness exceeding HRC 58, and are fitted with high-precision tolerances. More importantly, all connecting bolts generally employ mechanical anti-loosening measures such as double-nut locking, anaerobic adhesive anti-loosening, or disc spring washers to prevent preload attenuation due to vibration. For core reference points, a composite positioning method of tapered pins and end-face contact is often used, limiting both radial displacement and axial movement, significantly improving the consistency of repeated installations.

3. Material Selection and Thermal-Mechanical Stability Control

In addition to mechanical vibration, workshop temperature fluctuations also affect dimensional stability through thermal expansion and contraction. Therefore, frame welding processing tends to use materials with low coefficients of thermal expansion, or embed temperature compensation structures within ordinary steel. Simultaneously, all welded components must undergo stress-relief annealing before processing to eliminate residual stress and prevent slow deformation due to stress release during use. This "thermal-mechanical dual stabilization" strategy ensures that even after months or years of continuous use, the reference position drift remains within ±0.05 mm.

4. Regular Calibration and Condition Monitoring Mechanism

Even the most robust structures require maintenance. Advanced manufacturing companies generally establish periodic calibration systems, using laser trackers or coordinate measuring machines to re-measure key reference points of the inspection frame. If deviations exceed limits, adjustments or repairs are immediately made. Some intelligent inspection tools integrate miniature vibration sensors and displacement monitoring modules, which can record abnormal impact events in real time and provide early warnings of potential accuracy risks within the system, achieving a shift from "passive maintenance" to "predictive maintenance."

5. Installation Foundation and Vibration Isolation Measures

The installation platform of the inspection tool frame is equally crucial. Ideally, it should be fixed to an independent concrete foundation or heavy-duty vibration isolation platform to avoid sharing vibration sources with production line equipment. Anchor bolts are chemically anchored or welded with pre-embedded steel plates to ensure a rigid overall connection. In high-precision scenarios, active or passive vibration isolation pads are even used to further attenuate low-frequency vibrations transmitted from the ground.

The frame welding processing inspection tool achieves long-term, reliable, and repeatable positioning accuracy in continuously vibrating industrial environments through the synergistic effect of five dimensions: high-rigidity structural design, precision anti-loosening reference system, material thermal stability control, intelligent monitoring, and standardized installation. This not only ensures product quality consistency but also lays a solid foundation for online quality closed-loop control in intelligent manufacturing, truly becoming an indispensable "precision guardian" in modern welding workshops.