How can frame welding ensure the long-term stability of testing tools?

Release Time : 2025-10-30

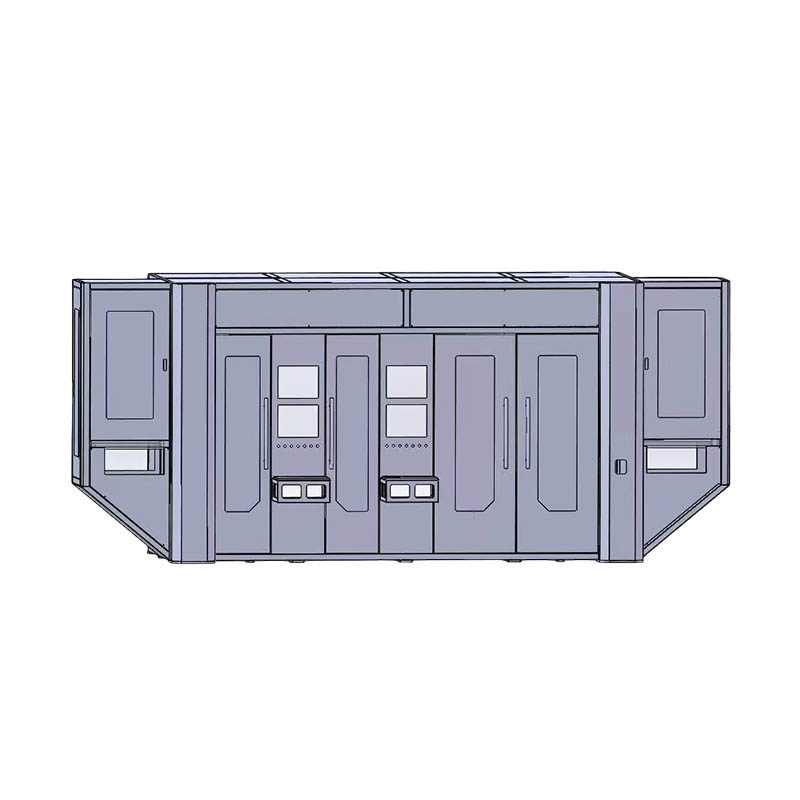

As the load-bearing platform for various diagnostic equipment, measuring instruments, and auxiliary devices, the long-term stability of the frame directly determines the reliability of testing results and operational efficiency. Under frequent movement, continuous load, and complex working conditions, deformation, loosening, or inaccuracy of the frame will lead to equipment positioning deviation, accumulated measurement errors, and even affect the safety of maintenance operations. Therefore, ensuring that the frame maintains structural stability, geometric accuracy, and functional integrity during long-term use is a core objective in design and manufacturing.

Stability stems first from the selection of materials and structural design. High-strength steel, due to its excellent tensile and compressive strength and rigidity, is the preferred material for frame welding. By rationally designing the cross-sectional shape and wall thickness, weight distribution can be optimized while ensuring load-bearing capacity, avoiding localized stress concentration. Frame welding typically employs a rectangular or trapezoidal topology, utilizing the principle of triangular stability to enhance overall rigidity. Key connection points and support areas are thickened or reinforced to cope with vibrations and impacts during equipment operation. A reasonable structural layout can also effectively distribute the load, ensuring that the weight is evenly transferred to the ground, reducing torsional deformation caused by center of gravity shift.

Frame welding is a crucial step in determining frame stability. Compared to bolted connections, welding achieves atomic-level bonding between metals, forming a continuous, seamless connection that significantly improves the structure's integrity and torsional resistance. High-quality welding requires not only full and uniform welds but also controlled heat input to prevent material microstructure changes or residual stress caused by localized overheating. Using techniques such as segmented welding and symmetrical welding reduces welding deformation, ensuring the frame maintains its design dimensions after cooling. Post-weld overall annealing or vibration aging effectively releases internal stress, preventing slow deformation due to stress release during long-term use.

Precision control in frame welding is maintained throughout the entire manufacturing process. From raw material cutting to component assembly, every step must strictly adhere to tolerance requirements. CNC cutting equipment ensures precise dimensions of each component, while specialized tooling fixtures guarantee accurate relative positioning of components during welding. Key mounting surfaces and positioning holes are precision milled in a machining center to ensure the flatness of the equipment mounting reference surface and the consistency of hole positions. This high-precision manufacturing provides a reliable foundation for subsequent equipment installation and calibration, avoiding repeated adjustments or measurement deviations caused by frame errors.

Surface treatment processes further enhance the durability of frame welding. Sandblasting or shot blasting not only removes scale and oil but also creates a uniform roughness on the metal surface, strengthening coating adhesion. Multi-layer spraying or powder coating forms a dense protective layer on the frame surface, resisting corrosion from oil, moisture, and chemical reagents, preventing structural weakening caused by rust. For frames that require frequent movement, the coating must also possess good abrasion resistance, resisting scratches and impacts.

Modular and adjustable design enhances the adaptability and long-term usability of the frame. Through standardized interfaces and adjustable supports, the frame can flexibly adapt to different brands and models of testing equipment, extending its service life. Even if equipment is upgraded or replaced in the future, the frame can still be adjusted for continued use, avoiding repeated investment. Integrated cable management channels and tool mounting points keep the work area neat and organized, reducing accidental damage caused by cable tangling or tool collisions.

Ultimately, the long-term stability of frame welding is a comprehensive reflection of materials, processes, design, and meticulous management. It not only ensures the accurate operation of testing tools but also improves the efficiency and safety of the maintenance workshop. A robust, reliable, and durable framework is the silent cornerstone for the efficient operation of modern automotive testing systems.

Stability stems first from the selection of materials and structural design. High-strength steel, due to its excellent tensile and compressive strength and rigidity, is the preferred material for frame welding. By rationally designing the cross-sectional shape and wall thickness, weight distribution can be optimized while ensuring load-bearing capacity, avoiding localized stress concentration. Frame welding typically employs a rectangular or trapezoidal topology, utilizing the principle of triangular stability to enhance overall rigidity. Key connection points and support areas are thickened or reinforced to cope with vibrations and impacts during equipment operation. A reasonable structural layout can also effectively distribute the load, ensuring that the weight is evenly transferred to the ground, reducing torsional deformation caused by center of gravity shift.

Frame welding is a crucial step in determining frame stability. Compared to bolted connections, welding achieves atomic-level bonding between metals, forming a continuous, seamless connection that significantly improves the structure's integrity and torsional resistance. High-quality welding requires not only full and uniform welds but also controlled heat input to prevent material microstructure changes or residual stress caused by localized overheating. Using techniques such as segmented welding and symmetrical welding reduces welding deformation, ensuring the frame maintains its design dimensions after cooling. Post-weld overall annealing or vibration aging effectively releases internal stress, preventing slow deformation due to stress release during long-term use.

Precision control in frame welding is maintained throughout the entire manufacturing process. From raw material cutting to component assembly, every step must strictly adhere to tolerance requirements. CNC cutting equipment ensures precise dimensions of each component, while specialized tooling fixtures guarantee accurate relative positioning of components during welding. Key mounting surfaces and positioning holes are precision milled in a machining center to ensure the flatness of the equipment mounting reference surface and the consistency of hole positions. This high-precision manufacturing provides a reliable foundation for subsequent equipment installation and calibration, avoiding repeated adjustments or measurement deviations caused by frame errors.

Surface treatment processes further enhance the durability of frame welding. Sandblasting or shot blasting not only removes scale and oil but also creates a uniform roughness on the metal surface, strengthening coating adhesion. Multi-layer spraying or powder coating forms a dense protective layer on the frame surface, resisting corrosion from oil, moisture, and chemical reagents, preventing structural weakening caused by rust. For frames that require frequent movement, the coating must also possess good abrasion resistance, resisting scratches and impacts.

Modular and adjustable design enhances the adaptability and long-term usability of the frame. Through standardized interfaces and adjustable supports, the frame can flexibly adapt to different brands and models of testing equipment, extending its service life. Even if equipment is upgraded or replaced in the future, the frame can still be adjusted for continued use, avoiding repeated investment. Integrated cable management channels and tool mounting points keep the work area neat and organized, reducing accidental damage caused by cable tangling or tool collisions.

Ultimately, the long-term stability of frame welding is a comprehensive reflection of materials, processes, design, and meticulous management. It not only ensures the accurate operation of testing tools but also improves the efficiency and safety of the maintenance workshop. A robust, reliable, and durable framework is the silent cornerstone for the efficient operation of modern automotive testing systems.