How can internal metal welding parts of automotive automation equipment maintain structural stability and prevent loosening in high-intensity vibration environments?

Release Time : 2025-10-16

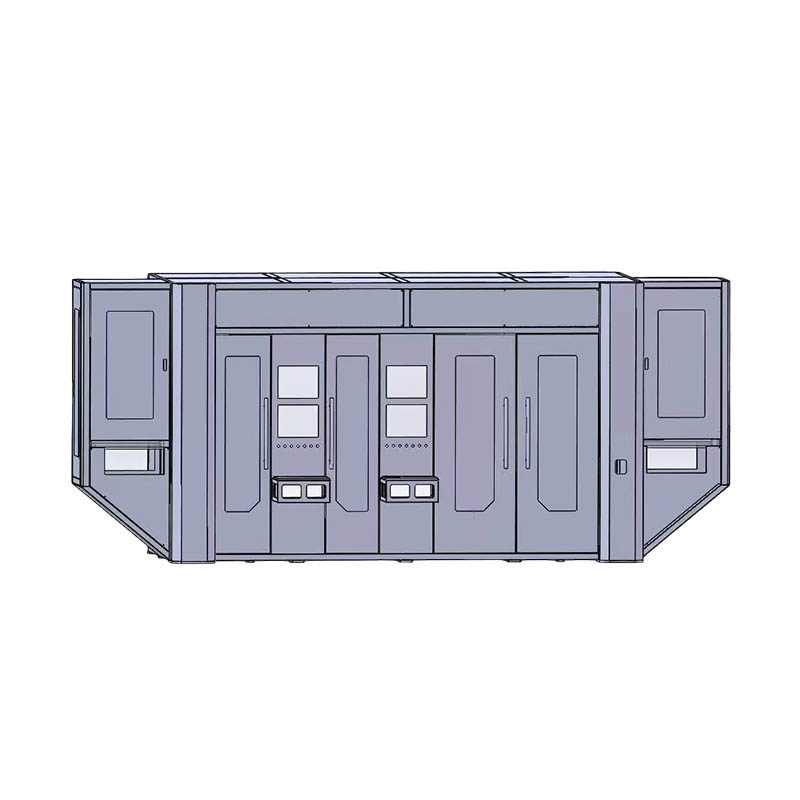

In modern automotive manufacturing plants, automated equipment such as welding robots, assembly lines, conveyor systems, and laser cutting machines operate at high speeds around the clock. Their internal structures are subjected to high-frequency vibration, cyclical shock, and dynamic loads. As key components of the equipment's framework and functional support, internal metal welding parts of automotive automation equipment not only bear loads, provide positioning, and transmit power, but also must maintain long-term structural stability under harsh operating conditions to prevent loosening, cracking, or fatigue failure that can lead to equipment downtime, reduced accuracy, and even accidents.

1. High-Strength Material Selection: Laying the Foundation for Vibration Resistance

Internal metal welding parts of automotive automation equipment are typically made of high-strength low-alloy steel, structural steel, or stainless steel. These materials offer excellent tensile strength, yield strength, and toughness. High yield strength makes the material less susceptible to plastic deformation in vibration environments, while good toughness effectively absorbs impact energy and prevents brittle fracture. For equipment with high lightweighting requirements, aluminum or titanium alloy welded structures are also used, and heat treatment is used to enhance their fatigue resistance, ensuring they resist deformation and disbonding during long-term vibration.

2. Optimizing Welded Structure Design: Improving Overall Rigidity and Stress Distribution

Rational structural design is key to vibration resistance. Engineers use finite element analysis to perform mechanical simulations on welded components, identify areas of stress concentration, and optimize the structural form. For example, reinforcing ribs, ribs, box beams, or arched structures are used to improve overall rigidity. Sharp corners are avoided, with rounded transitions employed to reduce stress concentration. Welds are placed in areas with low stress levels to avoid direct shear or tensile loads. Furthermore, a symmetrical weld layout ensures uniform stress distribution, reduces torsional vibration caused by eccentric loads, and thus improves structural stability.

3. Advanced Welding Processes: Ensuring Weld Density and Joint Strength

Welding quality directly determines joint strength. Automotive automation equipment commonly uses robotic welding techniques, such as MIG, TIG, or laser welding, to ensure uniform, continuous, and defect-free welds. Laser welding features high energy density, a small heat-affected zone, and a large depth-to-width ratio, enabling precise deep penetration welding with weld strength approaching that of the parent metal. Furthermore, multi-pass welding, preheating, and post-weld heat treatment processes eliminate residual stress, prevent weld cracking and deformation, and enhance weld fatigue resistance.

4. Weld Form and Joint Design: Enhancing Vibration Resistance

Common vibration-resistant weld joints include butt welds, fillet welds, lap welds, and plug welds. Fillet welds are widely used in frame connections and offer excellent shear resistance. Plug welds and slot welds are used at overlapping plate sections to effectively transfer loads and prevent interlaminar slip. Weld design utilizes continuous welding rather than intermittent welding to ensure continuous force transfer. Increased weld height or length is used in critical areas to enhance joint strength. Double-sided welding or full penetration welding is also used in some areas with high dynamic loads to ensure the weld extends through the entire joint thickness, eliminating premature cracking caused by incomplete penetration.

5. Anti-loosening and Vibration-Reducing Structural Design

Although welding itself is a permanent connection, under extreme vibration conditions, the surrounding structure of the weld can still cause fatigue cracks due to fretting wear. To this end, vibration-damping washers, rubber buffers, or elastic supports are often added to welded joints to absorb vibration energy. For bolted and welded composite structures, locking washers, threadlockers, or double nuts are used to prevent loosening of auxiliary fasteners and resonance.

6. Post-weld Treatment and Quality Inspection: Ensuring Long-Term Reliability

After completion, internal metal welding parts of automotive automation equipment undergo stress relief annealing or vibration aging treatment to eliminate internal residual stresses and prevent stress corrosion cracking. Anti-corrosion coatings are applied by sandblasting, electrophoresis, or spraying to prevent rust in humid environments, which accelerates fatigue crack propagation. Furthermore, non-destructive testing of critical welds using ultrasonic testing, X-ray testing, or magnetic particle testing ensures the absence of defects such as pores, slag inclusions, and cracks, eliminating potential risks at the source.

7. Modularity and Rigid Assembly: System-Level Vibration Resistance

Modern automation equipment utilizes a modular design. Each welded component undergoes precision assembly and dynamic balancing testing before shipment, ensuring high structural rigidity and a stable center of gravity. During equipment installation, vibration-damping feet, vibration isolation platforms, or flexible connections are used to further isolate external vibration sources.

The stability and firmness of internal metal welding parts of automotive automation equipment in high-intensity vibration environments is due to a comprehensive, integrated system of "high-quality materials + optimized design + precision craftsmanship + rigorous testing." This is more than just a simple metal connection; it's a systematic engineering project integrating mechanics, materials science, and intelligent manufacturing. It's this "invisible framework" that supports the efficient, stable, and safe operation of automotive production lines, providing a solid physical foundation for intelligent manufacturing.

1. High-Strength Material Selection: Laying the Foundation for Vibration Resistance

Internal metal welding parts of automotive automation equipment are typically made of high-strength low-alloy steel, structural steel, or stainless steel. These materials offer excellent tensile strength, yield strength, and toughness. High yield strength makes the material less susceptible to plastic deformation in vibration environments, while good toughness effectively absorbs impact energy and prevents brittle fracture. For equipment with high lightweighting requirements, aluminum or titanium alloy welded structures are also used, and heat treatment is used to enhance their fatigue resistance, ensuring they resist deformation and disbonding during long-term vibration.

2. Optimizing Welded Structure Design: Improving Overall Rigidity and Stress Distribution

Rational structural design is key to vibration resistance. Engineers use finite element analysis to perform mechanical simulations on welded components, identify areas of stress concentration, and optimize the structural form. For example, reinforcing ribs, ribs, box beams, or arched structures are used to improve overall rigidity. Sharp corners are avoided, with rounded transitions employed to reduce stress concentration. Welds are placed in areas with low stress levels to avoid direct shear or tensile loads. Furthermore, a symmetrical weld layout ensures uniform stress distribution, reduces torsional vibration caused by eccentric loads, and thus improves structural stability.

3. Advanced Welding Processes: Ensuring Weld Density and Joint Strength

Welding quality directly determines joint strength. Automotive automation equipment commonly uses robotic welding techniques, such as MIG, TIG, or laser welding, to ensure uniform, continuous, and defect-free welds. Laser welding features high energy density, a small heat-affected zone, and a large depth-to-width ratio, enabling precise deep penetration welding with weld strength approaching that of the parent metal. Furthermore, multi-pass welding, preheating, and post-weld heat treatment processes eliminate residual stress, prevent weld cracking and deformation, and enhance weld fatigue resistance.

4. Weld Form and Joint Design: Enhancing Vibration Resistance

Common vibration-resistant weld joints include butt welds, fillet welds, lap welds, and plug welds. Fillet welds are widely used in frame connections and offer excellent shear resistance. Plug welds and slot welds are used at overlapping plate sections to effectively transfer loads and prevent interlaminar slip. Weld design utilizes continuous welding rather than intermittent welding to ensure continuous force transfer. Increased weld height or length is used in critical areas to enhance joint strength. Double-sided welding or full penetration welding is also used in some areas with high dynamic loads to ensure the weld extends through the entire joint thickness, eliminating premature cracking caused by incomplete penetration.

5. Anti-loosening and Vibration-Reducing Structural Design

Although welding itself is a permanent connection, under extreme vibration conditions, the surrounding structure of the weld can still cause fatigue cracks due to fretting wear. To this end, vibration-damping washers, rubber buffers, or elastic supports are often added to welded joints to absorb vibration energy. For bolted and welded composite structures, locking washers, threadlockers, or double nuts are used to prevent loosening of auxiliary fasteners and resonance.

6. Post-weld Treatment and Quality Inspection: Ensuring Long-Term Reliability

After completion, internal metal welding parts of automotive automation equipment undergo stress relief annealing or vibration aging treatment to eliminate internal residual stresses and prevent stress corrosion cracking. Anti-corrosion coatings are applied by sandblasting, electrophoresis, or spraying to prevent rust in humid environments, which accelerates fatigue crack propagation. Furthermore, non-destructive testing of critical welds using ultrasonic testing, X-ray testing, or magnetic particle testing ensures the absence of defects such as pores, slag inclusions, and cracks, eliminating potential risks at the source.

7. Modularity and Rigid Assembly: System-Level Vibration Resistance

Modern automation equipment utilizes a modular design. Each welded component undergoes precision assembly and dynamic balancing testing before shipment, ensuring high structural rigidity and a stable center of gravity. During equipment installation, vibration-damping feet, vibration isolation platforms, or flexible connections are used to further isolate external vibration sources.

The stability and firmness of internal metal welding parts of automotive automation equipment in high-intensity vibration environments is due to a comprehensive, integrated system of "high-quality materials + optimized design + precision craftsmanship + rigorous testing." This is more than just a simple metal connection; it's a systematic engineering project integrating mechanics, materials science, and intelligent manufacturing. It's this "invisible framework" that supports the efficient, stable, and safe operation of automotive production lines, providing a solid physical foundation for intelligent manufacturing.