Does the inspection tooling frame for frame welding effectively resist the thermal deformation and mechanical stresses during welding?

Release Time : 2025-10-04

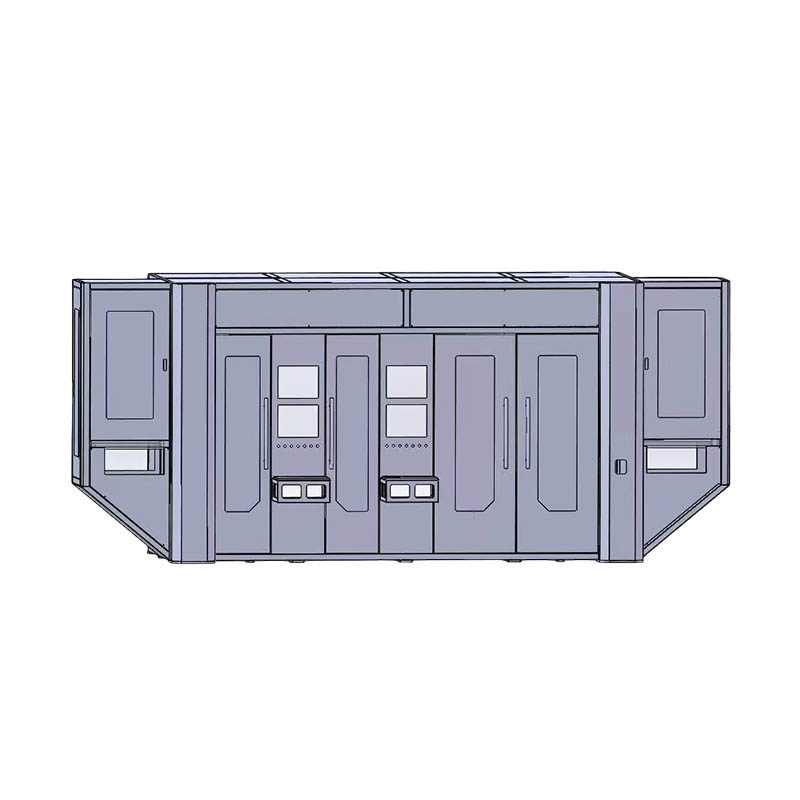

In automotive manufacturing, the frame is the core load-bearing structure of the entire vehicle. The quality of its welding directly impacts vehicle safety, durability, and assembly accuracy. The inspection tooling frame, an essential piece of equipment in the welding process, performs multiple functions, including positioning, clamping, inspection, and quality control. It serves not only as a reference platform for welding operations but also as a benchmark for ensuring the geometric consistency of each frame. However, during high-intensity, high-frequency welding operations, the inspection tooling frame itself faces severe challenges: the high temperatures generated by the welding arc, the thermal stresses caused by melting and cooling metal, and the mechanical loads from clamping and workpiece clamping all exert continuous stress on the inspection tool structure. Therefore, the inspection tooling frame's ability to resist thermal deformation and mechanical stress, and its ability to maintain structural stability and accuracy over long-term use, are key indicators of its quality and reliability.

High-quality inspection tooling frames for frame welding are designed with the rigors of real-world working conditions in mind. Its main structure is typically constructed of highly rigid materials, such as high-quality carbon steel or cast iron. After integral machining or welding, stress relief treatment is applied to effectively eliminate internal residual stresses and prevent distortion or deformation caused by stress release during subsequent use. This structural stability is the first line of defense against external interference. Furthermore, the inspection tool's skeleton layout has been mechanically optimized, with thickened and reinforced critical stress-bearing areas and securely connected support columns to the base, forming a stable three-dimensional framework. This evenly distributes localized stresses generated during welding, preventing stress concentrations that could lead to localized deformation or fatigue cracking.

To mitigate thermal deformation, the design of the inspection tooling frame emphasizes thermal stability. Welding areas typically generate localized high temperatures. If the inspection tool's material conducts heat unevenly or its structure is asymmetrical, deformation due to differential thermal expansion is highly likely. Therefore, high-quality inspection tooling frames employ thermal insulation or use materials with low thermal expansion coefficients near the weld points to minimize the impact of heat conduction on the reference surface. Furthermore, positioning elements and clamping mechanisms are positioned as far away from direct heat sources as possible to prevent softening or deformation due to high temperatures, which could affect positioning accuracy. Some high-end inspection tools also incorporate heat sinks or ventilation structures in key locations to accelerate heat dissipation and maintain uniform temperature distribution.

In addition, the manufacturing process of the inspection tooling frame also determines its long-term stability. All key components, such as datum surfaces, locating pin holes, and clamping bases, undergo precision machining and surface treatment to ensure dimensional accuracy, wear resistance, and corrosion resistance. During assembly, each component is rigorously calibrated according to design specifications, ensuring that the positioning system and the measurement datum are highly consistent. This high-precision initial state lays the foundation for long-term accuracy maintenance. Furthermore, inspection tooling frames typically undergo extensive stability testing before commissioning. Repeated clamping and thermal cycling simulate actual welding conditions to verify their performance under dynamic loads and ensure stable production upon delivery.

In actual use, a highly deformable inspection tooling frame can maintain accurate positioning through tens of thousands of welding cycles. Whether operated by a new employee or in continuous production, each clamping replicates the same datum state, ensuring that key parameters such as weld point position, hole spacing, and profile dimensions remain within tolerance. This consistency not only improves welding quality but also reduces rework and scrap, ensuring smooth vehicle assembly.

More importantly, a stable inspection tooling frame provides reliable data support for process optimization. Through long-term measurement feedback, companies can analyze welding deformation trends, adjust welding sequences or clamping strategies, and further improve process performance. However, if the inspection tool itself is deformed or misaligned, all inspection data becomes invaluable, potentially misleading process decisions.

In summary, the reliability of a vehicle frame welding inspection tooling frame as a "quality benchmark" depends on its ability to effectively withstand the thermal deformation and mechanical stresses of the welding process. Through a highly rigid structural design, effective thermal management, precision manufacturing, and rigorous verification, a high-quality inspection tooling frame maintains stable shape and accurate positioning during long-term, high-load operation, making it a trusted "silent guardian" of the welding production line. In modern manufacturing systems that strive for high precision, efficiency, and consistency, this stability is the core guarantee for achieving exceptional quality.

High-quality inspection tooling frames for frame welding are designed with the rigors of real-world working conditions in mind. Its main structure is typically constructed of highly rigid materials, such as high-quality carbon steel or cast iron. After integral machining or welding, stress relief treatment is applied to effectively eliminate internal residual stresses and prevent distortion or deformation caused by stress release during subsequent use. This structural stability is the first line of defense against external interference. Furthermore, the inspection tool's skeleton layout has been mechanically optimized, with thickened and reinforced critical stress-bearing areas and securely connected support columns to the base, forming a stable three-dimensional framework. This evenly distributes localized stresses generated during welding, preventing stress concentrations that could lead to localized deformation or fatigue cracking.

To mitigate thermal deformation, the design of the inspection tooling frame emphasizes thermal stability. Welding areas typically generate localized high temperatures. If the inspection tool's material conducts heat unevenly or its structure is asymmetrical, deformation due to differential thermal expansion is highly likely. Therefore, high-quality inspection tooling frames employ thermal insulation or use materials with low thermal expansion coefficients near the weld points to minimize the impact of heat conduction on the reference surface. Furthermore, positioning elements and clamping mechanisms are positioned as far away from direct heat sources as possible to prevent softening or deformation due to high temperatures, which could affect positioning accuracy. Some high-end inspection tools also incorporate heat sinks or ventilation structures in key locations to accelerate heat dissipation and maintain uniform temperature distribution.

In addition, the manufacturing process of the inspection tooling frame also determines its long-term stability. All key components, such as datum surfaces, locating pin holes, and clamping bases, undergo precision machining and surface treatment to ensure dimensional accuracy, wear resistance, and corrosion resistance. During assembly, each component is rigorously calibrated according to design specifications, ensuring that the positioning system and the measurement datum are highly consistent. This high-precision initial state lays the foundation for long-term accuracy maintenance. Furthermore, inspection tooling frames typically undergo extensive stability testing before commissioning. Repeated clamping and thermal cycling simulate actual welding conditions to verify their performance under dynamic loads and ensure stable production upon delivery.

In actual use, a highly deformable inspection tooling frame can maintain accurate positioning through tens of thousands of welding cycles. Whether operated by a new employee or in continuous production, each clamping replicates the same datum state, ensuring that key parameters such as weld point position, hole spacing, and profile dimensions remain within tolerance. This consistency not only improves welding quality but also reduces rework and scrap, ensuring smooth vehicle assembly.

More importantly, a stable inspection tooling frame provides reliable data support for process optimization. Through long-term measurement feedback, companies can analyze welding deformation trends, adjust welding sequences or clamping strategies, and further improve process performance. However, if the inspection tool itself is deformed or misaligned, all inspection data becomes invaluable, potentially misleading process decisions.

In summary, the reliability of a vehicle frame welding inspection tooling frame as a "quality benchmark" depends on its ability to effectively withstand the thermal deformation and mechanical stresses of the welding process. Through a highly rigid structural design, effective thermal management, precision manufacturing, and rigorous verification, a high-quality inspection tooling frame maintains stable shape and accurate positioning during long-term, high-load operation, making it a trusted "silent guardian" of the welding production line. In modern manufacturing systems that strive for high precision, efficiency, and consistency, this stability is the core guarantee for achieving exceptional quality.