How does high-strength alloy steel ensure long-term stability of inspection tools?

Release Time : 2025-09-08

In the precision halls of modern automotive manufacturing, frame welding is a core process that builds the "skeleton" of the entire vehicle. Its accuracy directly determines the vehicle's safety, handling, and assembly quality. Behind this rigorous process, the German Volkswagen Inspection Tooling Frame acts as a silent "ultimate examiner." With its unparalleled precision, rigorous construction, and exceptional German-made quality, it provides the most authoritative verification of the geometric dimensions and assembly relationships of each frame. It is not only the cornerstone of quality control but also the precise bridge that transforms design blueprints into flawless vehicles. Its very existence is a solemn expression of the spirit of "German Precision."

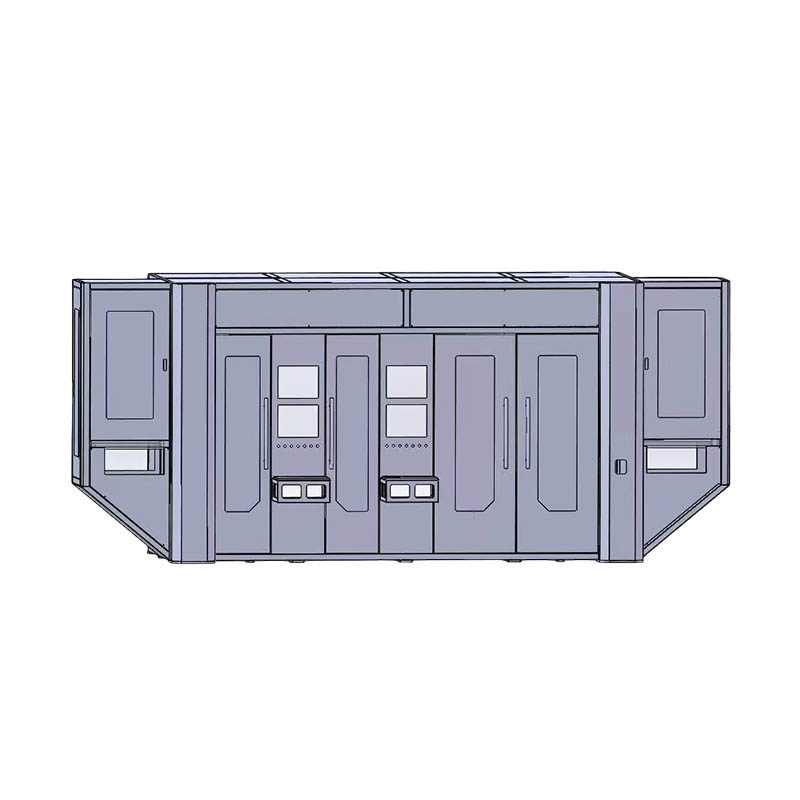

The inherent beauty of the German Volkswagen Inspection Tooling Frame stems from the harmonious integration of "precision engineering" and "industrial sculpture." Its aesthetic is primarily reflected in the order and strength embodied in its massive and complex mechanical structure. The entire inspection tooling frame is typically precision-machined from high-strength alloy steel or cast iron, resulting in a sturdy and stable structure that resists deformation during long-term use. It's densely packed with hundreds of locating pins, measuring holes, datum surfaces, clamping devices, and data acquisition probes. The position of each component is precisely calculated and calibrated to the millimeter or even micron level. When the vehicle frame is hoisted and precisely positioned on the German Volkswagen Inspection Tooling Frame, these locating pins, like "keys," seamlessly engage with the "lockholes" on the frame, instantly securing the frame in its designed position. This sense of "clicking"—derived from absolute precision—creates a unique mechanical aesthetic. Its "industrial sculpture" beauty lies in its overall form. While functionality is paramount, its rational layout, orderly piping, and user-friendly operating space create a grand sense of order born of efficiency and rigor. In the modern assembly shop, the German Volkswagen Inspection Tooling Frame stands quietly like a giant piece of metal art, exuding a cool, professional, and reliable industrial aura.

Its unique characteristics are rooted in the in-depth integration of "ultra-high precision," "strict standards," and "efficient testing." Its core feature lies in its "ultra-high precision" measurement capabilities. The German Volkswagen Inspection Tooling Frame is designed and manufactured in accordance with the Volkswagen Group's stringent, globally standardized standards (such as VW 60300). Its manufacturing precision far exceeds the tolerance requirements of the vehicle frame. It rapidly and accurately inspects hundreds of critical points on the frame (such as suspension points, engine mounting points, and body coordinate system reference points), ensuring that every dimension, axis, and hole position conforms to design specifications. This "zero tolerance" precision control is crucial for ensuring smooth final assembly and consistent vehicle quality. Its stringent standards are the source of its authority. As a key entry point into the Volkswagen Group's supply chain, the German Volkswagen Inspection Tooling Frame signifies that suppliers' production processes and product quality meet the stringent requirements of the Volkswagen global system. It is more than just an inspection tool; it serves as a component of quality system certification, ensuring consistency and traceability from component to vehicle.

"Efficient inspection" is key to its adaptation to the pace of modern production. Traditional three-dimensional coordinate measurement is time-consuming, but the German Volkswagen Inspection Tooling Frame enables "one-click" or "quick-check" inspection of critical vehicle frame dimensions, significantly reducing inspection time and meeting the cycle times of assembly line production. Combined with a data acquisition system, inspection results can be uploaded to the quality management system in real time, enabling digital and traceable quality control.

The German Volkswagen Inspection Tooling Frame is the ultimate guardian of automotive quality. Its German precision craftsmanship sets the absolute benchmark for inspection; its ultra-high accuracy verifies the accuracy of vehicle frames to the millimeter; and its rigorous standards define the highest standards of global manufacturing quality. Every precise connection between the frame and the production line is more than just a physical fix; it serves as a solemn affirmation of our commitment to design, craftsmanship, and quality. It proves that the greatest innovations often lie in the most fundamental principles. Choosing the German Volkswagen Inspection Tooling Frame means choosing the rigor and reliability of German manufacturing for your automotive manufacturing. It silently guards the most precise dimensions with the hardest metal. It is the uncompromising "stabilizing force" in the crown of the modern automotive industry, ensuring that every car rolling off the production line carries the promise of safety and trust.

The inherent beauty of the German Volkswagen Inspection Tooling Frame stems from the harmonious integration of "precision engineering" and "industrial sculpture." Its aesthetic is primarily reflected in the order and strength embodied in its massive and complex mechanical structure. The entire inspection tooling frame is typically precision-machined from high-strength alloy steel or cast iron, resulting in a sturdy and stable structure that resists deformation during long-term use. It's densely packed with hundreds of locating pins, measuring holes, datum surfaces, clamping devices, and data acquisition probes. The position of each component is precisely calculated and calibrated to the millimeter or even micron level. When the vehicle frame is hoisted and precisely positioned on the German Volkswagen Inspection Tooling Frame, these locating pins, like "keys," seamlessly engage with the "lockholes" on the frame, instantly securing the frame in its designed position. This sense of "clicking"—derived from absolute precision—creates a unique mechanical aesthetic. Its "industrial sculpture" beauty lies in its overall form. While functionality is paramount, its rational layout, orderly piping, and user-friendly operating space create a grand sense of order born of efficiency and rigor. In the modern assembly shop, the German Volkswagen Inspection Tooling Frame stands quietly like a giant piece of metal art, exuding a cool, professional, and reliable industrial aura.

Its unique characteristics are rooted in the in-depth integration of "ultra-high precision," "strict standards," and "efficient testing." Its core feature lies in its "ultra-high precision" measurement capabilities. The German Volkswagen Inspection Tooling Frame is designed and manufactured in accordance with the Volkswagen Group's stringent, globally standardized standards (such as VW 60300). Its manufacturing precision far exceeds the tolerance requirements of the vehicle frame. It rapidly and accurately inspects hundreds of critical points on the frame (such as suspension points, engine mounting points, and body coordinate system reference points), ensuring that every dimension, axis, and hole position conforms to design specifications. This "zero tolerance" precision control is crucial for ensuring smooth final assembly and consistent vehicle quality. Its stringent standards are the source of its authority. As a key entry point into the Volkswagen Group's supply chain, the German Volkswagen Inspection Tooling Frame signifies that suppliers' production processes and product quality meet the stringent requirements of the Volkswagen global system. It is more than just an inspection tool; it serves as a component of quality system certification, ensuring consistency and traceability from component to vehicle.

"Efficient inspection" is key to its adaptation to the pace of modern production. Traditional three-dimensional coordinate measurement is time-consuming, but the German Volkswagen Inspection Tooling Frame enables "one-click" or "quick-check" inspection of critical vehicle frame dimensions, significantly reducing inspection time and meeting the cycle times of assembly line production. Combined with a data acquisition system, inspection results can be uploaded to the quality management system in real time, enabling digital and traceable quality control.

The German Volkswagen Inspection Tooling Frame is the ultimate guardian of automotive quality. Its German precision craftsmanship sets the absolute benchmark for inspection; its ultra-high accuracy verifies the accuracy of vehicle frames to the millimeter; and its rigorous standards define the highest standards of global manufacturing quality. Every precise connection between the frame and the production line is more than just a physical fix; it serves as a solemn affirmation of our commitment to design, craftsmanship, and quality. It proves that the greatest innovations often lie in the most fundamental principles. Choosing the German Volkswagen Inspection Tooling Frame means choosing the rigor and reliability of German manufacturing for your automotive manufacturing. It silently guards the most precise dimensions with the hardest metal. It is the uncompromising "stabilizing force" in the crown of the modern automotive industry, ensuring that every car rolling off the production line carries the promise of safety and trust.