Increase the Quality Inspection Process to Improve Product Quality and Reduce Rework Rate and Return Rate

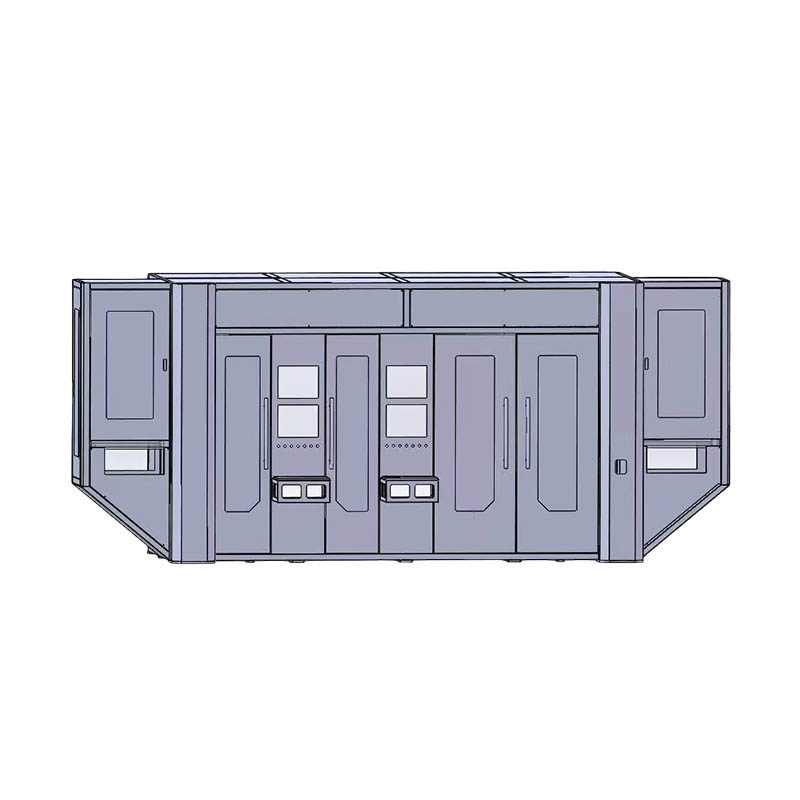

Our company provides automated equipment manufacturing (for sheet metal, welded parts, and machined parts) for Shanghai Shubo Machinery Equipment Co., Ltd. We have added the following processes, from product self-inspection to shipping inspection, to ensure product quality and qualification rates.

1. Welding Department (After the riveting and welding process is completed, the 3D model is compared with the drawings for complete accuracy before being sent to the welding department).

2. Sheet Metal Department (After processing, qualified parts are sent to the spraying area after inspection).

3. Finishing Department (Before parts leave the machine, they are inspected and verified for accuracy before being sent to the next department).

4. Assembly Department (Before spraying, parts are tested and confirmed for accuracy before being sent for spraying. After the parts return, the appearance is inspected).

5. Shipping Inspection Department (Individual parts are inspected and reported, and batches of parts are inspected and tested).